Industry-Flexible Solutions: Process Monitors

Anton Paar process monitors are smart sampling and measuring systems combined with an evaluation unit that delivers primary and derived parameters to the process control system. We offer robust solutions for hazardous areas (Ex Zones) as well as systems for chemically aggressive applications.

For extended functionality, such as automatic interlock or basic dosing control, we can deliver a process monitor with a control unit. The analysis software Davis 5 facilitates data analysis and reporting right from your desktop.

Our process monitors are easy to integrate and built to your requirements. Tell us about what you need, and we will implement our own or third-party sensors to fit your process, space, and materials.

Key features

Accurate measurements under all process conditions

We have solutions for all fields of applications, including inline adapters for low-viscosity fluids and liquid gases, and bypass solutions with sample pumps for media with higher viscosity or low flow rates. You can choose from various operating modes to facilitate measurement, cleaning, and sample drawing. By using our sensors or selected, high-quality third-party sensors, you get the highest precision – independent of media properties.

Fast integration, low costs

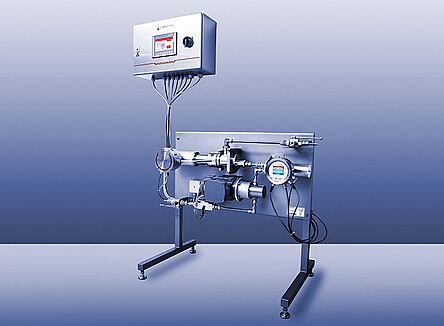

Our process monitors – with their space-saving design – are pre-assembled, wired, tested, and calibrated in the factory, which reduces the effort needed for installation, integration, and commissioning at your site to a minimum.

Powerful control unit for successful process control

Equipped with a control unit, process monitors are a key factor for successful process control. The PLC-based controller is programmed according to process requirements. It enables real-time monitoring of product specifications and online evaluation of data for quick analysis. On top of that, the controller has basic automation functions, such as machine interlock and simple dosing control, and allows for stand-alone or remote operation by the supervisory control system.

Full traceability, reliable evidence

Right from your desktop, control room, or calibration lab, you can use the analysis software Davis 5 for data logging and quality reporting. This software provides you with the statistical evaluation and traceability of production line performance and product quality that you need. With it, you can trace calibration and adjustment activities and data, which gives you reliable evidence of your measuring quality. It also smoothly transfers laboratory reference values into the process instruments.

A glimpse from the field: Kinematic Viscosity Monitor for lube oil blending

Our Kinematic Viscosity Monitor is equipped with the viscosity sensor L-Vis 510 or L-Vis 520 and the density sensor L-Dens 7400, which ensures continuous, high-precision measurements of dynamic viscosity, density, and temperature under process conditions. The built-in controller calculates the kinematic viscosity at reference temperatures (e.g., 40 °C and 100 °C) according to ASTM D341.

Via continuous product sampling, the Kinematic Viscosity Monitor gives you stable results and resistance to variations of flow, pressure, and temperature. Designed as a controller with a 7-inch touch panel, it’s safe and convenient to operate. It offers quality monitoring and has an interlock function, along with a fieldbus connection for remote operation. There’s also a version available for operation in hazardous environments.