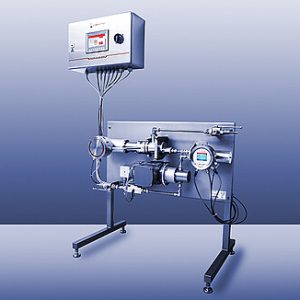

The Flex-Blend 7000 Series

The Flex-Blend series is a modular, inline blending, carbonating, and dosing solution that consists of autonomous, skid-mounted process modules. Based on your requirements, these modules can be integrated into your production line – no matter what kind. That’s not to mention its modular structure, which gives it a compact design and small footprint.

Key features

Easy setup, quick installation

The Flex-Blend series comes with all of the required electrical and mechanical components in one compact, skid-mounted system. It’s preconfigured, wired, and factory-tested when delivered. Our comprehensive factory testing guarantees minimal implementation effort and risk on your end and ensures a short production ramp up time for any systems purchased.

Direct control for what matters

With Flex-Blend 7000, you have your mixing ratio under control and can respond quickly to process variations and disturbances. Your production benefits from the highest dynamic control, precision, and accuracy over a wide operating range. Flex-Blend utilizes an optimized controller structure and control valve design to directly control concentrations by adjusting the amount of injected CO2 and added de-aerated water.

Broad dosing range for all beverages

Flex-Blend ensures complete mixing and dissolving over a wide dosing range. It’s suitable for all beverages requiring dosing from 0.1 g/L to 7 g/L CO2. It uses parallel control valves to achieve this wide dosing range with the highest precision. The integrated pump, a highly efficient CO2 injector, and a thoroughly dimensioned mixing section all guarantee high performance.

Reliable quality for the whole production process

Anton Paar’s Beverage Monitor 5600 with the optical CO2 sensors Carbo 6100/6300 is part of Flex-Blend. The short measuring and response times of the sensors are the basis for fast and precise controlling of mixing and dosing.

Low maintenance, low operating costs

The Flex-Blend series’ sensors don’t require maintenance. For parts that wear down (e.g., elastomers), all you have to do is check and replace them occasionally. Since valves and pumps are easily accessible, maintenance is quick.

High module integration

You can integrate any Flex-Blend 7000 module into any comprehensive system. Since the blender, carbonator, flavor dosing, buffer tanks, and water de-aeration systems are synchronized and operated by a single human machine interface (HMI), you can integrate any Flex-Blend 7000 module into any comprehensive system. Set it up to interact with a supervisory control system for remote operation, or let Flex-Blend take over the control of adjoining process systems.