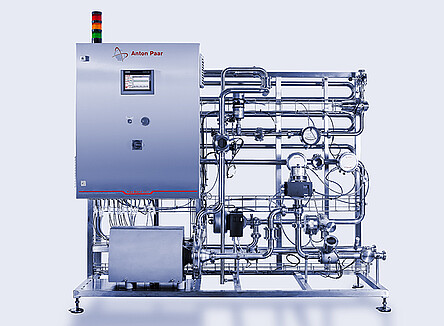

Flex-Blend 3000 Series

Without compromising on quality or specifications, Flex-Blend 3000 delivers the fastest and most precise alcohol, OE, and CO2 monitoring on the market in an all-in-one package at a top price-performance ratio.

These compact, maintenance-free carbonators and blenders offer recipe-specific calibration for optimized management of an unlimited number of product types, helping you avoid product loss and ensuring minimum changeover time. Combined with unique pre-delivery testing of the entire specifications range, they let you cover all future product and dosing choices and unleash your creativity.

Building on more than 50 years of experience working in the brewing industry, we continue to supply the highest-quality and most flexible process systems on the market.

Key features

Top price-performance ratio

- Our sensors ensure continuous accurate measurements for excellent quality control

- Fastest continuous measurement of concentration values on the market (one second measuring cycles) ensure rapid and precise control of ABV, OE, and CO2

- All-in-one package includes Anton Paar’s Beer Monitor 5600 with all sensors at an unbeatable price (approx. 30 % less expensive than buying it separately)

Tried-and-tested customer-specific solution and quick commissioning

- Flex-Blend’s Factory Acceptance Test (FAT) covers your full production spectrum and gives you the peace of mind that comes with knowing you’ve chosen the right supplier

- Comprehensive testing in the factory guarantees minimal implementation effort and risk, giving you short production ramp up times for any systems purchased

- Customers can attend FAT in person or online (via AnyDesk, Webex, etc.)

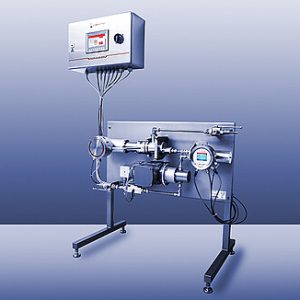

Small volume and compact footprint

- Fits anywhere – even under extreme space constraints

- Inline solution without tanks reduces product losses to a minimum, even for small production batches (small overall system volume of 12 liters – DN 40)

Maintenance-free design and highest technical availability

- Service-friendly design and maintenance-free sensors ensure low operating costs

- Flex-Blend 3000 offers remote access for service support with short reaction times at any time

Simple and powerful multi-product management

- Intelligent recipe management via integrated PLC with a touchscreen simplifies your handling of multiple products and production batches

- Improved batch-to-batch continuity (less than 30 seconds to produce according to specs after a batch starts) of QC parameters is based on recipe-specific management of calibration data and controller settings, which results in less waste and higher productivity

- Calibrating the Flex-Blend 3000 system with reference values measured by our laboratory instrumentation (e.g., Alex 500 alcohol meter, DMA density meters, CarboQC CO2 meter) ensures no out-of-spec production

Quality assurance and tracking

- Flex-Blend 3000 provides documented quality and reports per production lot without the need of a Supervisory Control and Data Acquisition (SCADA)

- Davis 5 records and archives production data in a database for real-time documentation, enabling closer alignment to exact product specifications

- Generates reports for in-spec production, which guarantees correct product declaration – especially for alcohol content