Automated Rheometer Workflow:

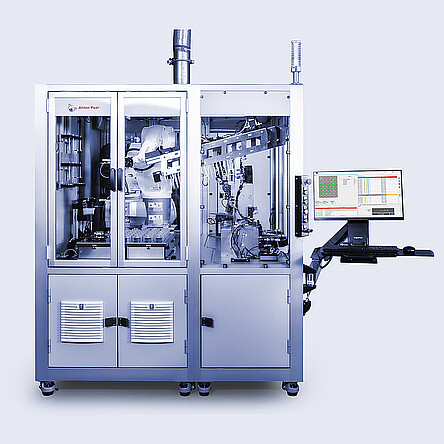

HTR 7000

The HTR 7000 performs fully automated traceable rheological measurements for solid, paste-like, or dispensable low-viscosity samples. Covering everything from sample preparation to cleaning, it eliminates up to 14 manual steps – freeing up entire shifts of R&D or QC work. Thanks to its modular design, it simplifies workflows, enhances data quality, and boosts productivity. HTR 7000 future-proofs your lab, accelerates innovation, streamlines operations, and maximizes repeatability – and all from one trusted provider.

Key features

Load. Set. Go.

Say goodbye to manual processes with HTR 7000’s automated workflows and optimize the value stream of your lab. Capable of running up to 60 samples and 14 workflow steps without interruption or supervision, the 24/7 automation handles prep, trimming, rheology and pH measurement, cleaning, and data transfer – freeing you to focus on more valuable tasks and research goals.

Reproducible data quality and full traceability

Automated sample preparation and measurement ensure dependable, precise results – every time. Integrated tools such as sample management, barcode reading, and LIMS connectivity guarantee SOP compliance and full traceability – further enhanced by image documentation for each measurement. Automated sample handling and trimming deliver maximum reproducibility (±2 %), while an optional dual rheometer setup enables parallel measurements – saving time and maximizing throughput with consistent performance. With HTR 7000, your lab is ready to produce data at scale, including for training AI models.

Maximum flexibility through modular design

Trust your results. Whether you’re working with solid, paste-like, or dispensable low-viscosity samples, HTR 7000 is suitable for all sample types that are measured with plate-plate or cone-plate measurement geometries. Configure the HTR 7000 with cleaning stations, various sample racks, geometry pairs (CP, PP), and an optional tempered rack for temperature control – tailored to any workflow or project requirement.

Safely open the door to rheology

The HTR 7000 is so safe that virtually anyone can use it. Its automated workflows minimize human interaction with harmful samples or cleaning agents, and completely eliminate contact with hot instrument geometries. Additional safety features, including safety doors, monitored ventilation, and an explosion-safety option, ensure confident operation at all times.

Precision meets performance

Alongside Anton Paar’s three-year standard warranty, you’ll benefit from best-in-class service, tailored wear and spare part packages, and expert support that guarantees punctual delivery, maximum uptime, and efficient knowledge transfer.

With subsidiaries around the globe, our global sales and service network is always nearby – offering comprehensive training, on-site and remote support, and personalized maintenance and service.