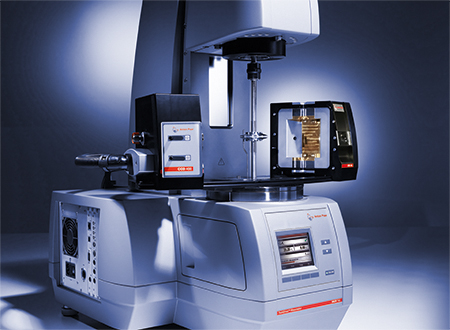

Rheometer : MCR 702 TwinDrive

Technical highlights

- TwinDrive technology: Two powerful, synchronous EC motor drives in one single modular setup

- IsoLign Piezo flange: Complete stepless gap control down to sizes of 10 nanometers

- Fully digital instrument employing the latest DSP (Digital Signal Processing) technology

- Two high-precision air bearings, including two patented normal force sensors

- TruGap™: Innovative and patented system for measuring the gap

- TruRate™: Sample-adaptive controller in rotation and step strain

- TruStrain™: Fast and accurate strain control due to improved real-time position control oscillation (DSO)

- Intuitive color display

Available test modes employing TwinDrive technology

- 2EC mode: Both motors operate as drive units and torque transducers and are used in different test modes

- counter-rotation

- separate motor transducer

- EC mode: Single-motor operation as known from the established MCR series, incorporating the entire range of MCR measuring and environmental systems

Ease of use

- Toolmaster™: Patented system for automatic recognition of measuring systems, accessories and TwinDrive motor

- Quickfit coupling: Easy, one-hand measuring system connection in both drive units

- T-Ready™: Reduced waiting times by detecting and signaling sample temperature equilibration

- Wide range of measuring systems for all kinds of applications

- USB connection to computer/software

- Ethernet connection for remote control of the instrument through the company network

- RheoCompass™: User-friendly application software

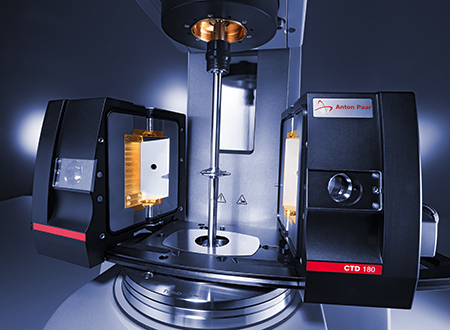

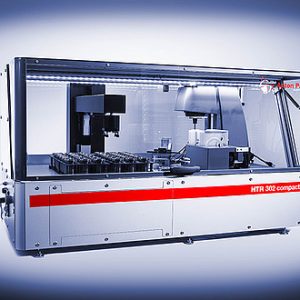

Wide range of accessories

- Devices for temperature control ranging from –150 °C to 1000 °C

- Special accessories for DMA™ and DMTA measurements, rheo-optics, magneto- and electrorheology, interfacial rheology, UV curing and many other applications