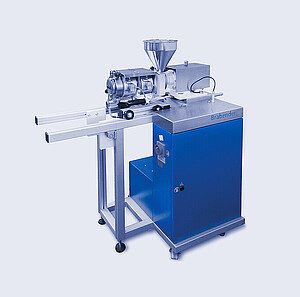

Lab- and Pilot-Scale Twin Screw Extruders:

TwinLab

Experience the future of lab extrusion with the Brabender Twin Screw Extruders – the TwinLab series – which provides various configurations to process everything from liquids to pellets. Streamline your material testing for lab and pilot-scale setups, and optimize your extrusion production process. MetaBridge operating software ensures intuitive device control, paired with comprehensive features and data analytics. It lets you access data from any device at any time. TwinLab’s smart clam shell design makes the liner easy to access and clean. The modular TwinLab series is powered by the MetaStation drive unit and offers twin- and single-screw extrusion as well as batch-wise mixing.

Key features

Gain insights with lab-scale extrusion data

Our Twin Screw Extruders – the TwinLab series – are measuring extruders for lab and pilot scale that provide comprehensive diagrams with recorded measurement parameters, letting you gain a deeper understanding of the materials you’re working with. Every step of the process is tracked and recorded, giving you insights into the characteristics of the extruded materials. This lets you adapt parameters, recipes, and configurations with pin-point accuracy, and reduces setup times and sample waste.

Measure results across platforms for better collaboration

Our MetaBridge operating software offers cross-platform access to measuring results, letting you access your recorded data from any device and location. This translates into maximum operator convenience and no transcription errors. You can easily export and provide data to colleagues and third-party systems and even send measuring data per email directly from the extruder. You can measure the following crucial parameters in the extrusion process:

- Temperature

- Pressure

- Torque

- Drive load

- And more…

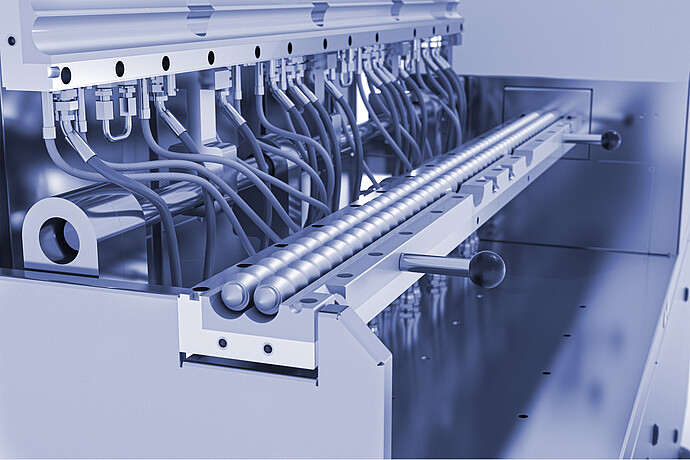

Working in tough environments? Need easy cleaning? No problem

Our steel alloys for liners, screws, and dies have been designed to cope with abrasive applications. They can withstand temperatures above 500 °C. Whether you’re working with highly corrosive or highly abrasive substances, our alloy will provide the durability you need. Because of the patented clam shell design with split and openable liners, you can easily monitor your screw configuration and processes as well as clean the screws and liners easily. This lets you keep your instrument clean and well-maintained – even in tough and abrasive applications.

Stay flexible with extruders of various sizes

Leverage extruders in various sizes and throughputs to meet your specific needs. Our range of extruders covers low and high-power applications. With throughputs ranging from 0.05 kg to 100 kg per hour, we cater to R&D labs and pilot scale production.

Modular extrusion solutions from a single supplier

The full Brabender twin-screw extrusion line solution is a modular plug-and-play system that combines extruders, feeders, pumps, dies, and downstream equipment. This means you get a complete extrusion line from a single supplier with a single point of contact, minimal setup costs, and quick startup time. Our modular extrusion solutions are powered by MetaStation drive units and let you easily switch between twin-, single-screw extrusion, and batch-wise mixing, all while providing the full spectrum of measuring parameters and analysis options of the stand-alone extruders. So even if you have limited space or budget, extrusion and mixing is accessible for you.

Your partner for special applications, customized solutions

Based on decades of experience in extrusion and vast application know-how, we find solutions where others don’t. We test your material and provide tailored solutions. With our in-house production and a dedicated R&D team, we even develop and supply customized solutions for all kinds of specific applications. Don’t hesitate to contact us in order to discuss your requirements and to find a customized solution for your extrusion task.