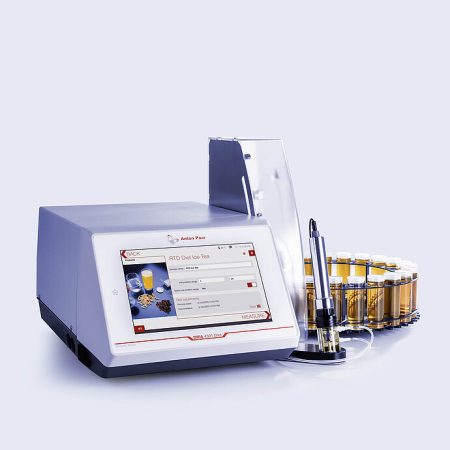

Soft Drink Measuring System 3001

Our Soft Drink Measuring System monitors the production of your regular and diet drinks from syrup to the finished product. The analyzing system determines °Brix and %Diet concentration and can be upgraded with different types of sample changers for automated filling and cleaning. Obtain precise results for exact dilution ratio setting, track and eliminate variations in your production, and achieve consistency in every batch.

Key features

Analyze your entire portfolio of soft drinks and ready-to-drink beverages

- Monitor your entire production process

- Analyze all kinds of (diet) syrups and final beverages

- Safeguard final product quality and eliminate out-of-spec production

Optimize your measurement processes with automation

- Conduct automated measurements with a Xsample 520 sample changer, which fills up to 24 samples in a row

- Ensure accurate results without operator influence

- Free up lab capacities for other tasks – once started, the system does its job without user interaction

Get 6x quicker results than with conventional methods

- Determine %Diet concentration, °Brix, and pH at the same time

- Reduce diet reference analysis time by 75 %

- Obtain reproducible results with a minimum of reference measurements with our patented Pulsed Excitation Method

Make QC easier with intuitive software

- Conduct QC without special training due to a software-guided adjustment procedure

- Ensure accurate results with FillingCheck™, an automatic bubble-detection feature, and U-ViewTM, which provides visual inspection of the density measuring cell via high-resolution camera

- Manage your data with AP Connect, our lab execution software