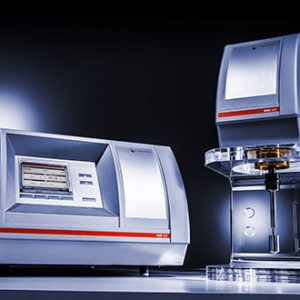

Rheometer: MCR 102, 302, 502

Technical highlights

- Powerful, synchronous EC motor drive

- Fully digital instrument employing the latest DSP (Digital Signal Processing) technology

- High-precision air bearing, including patented normal force sensor

- TruGap™: Innovative and patented system for measuring the gap

- TruRate™: Sample-adaptive controller in rotation and step strain

- TruStrain™: Fast and accurate strain control due to improved real-time position control oscillation (formerly DSO)

- Intuitive color display

- Different MCR models with outstanding specifications for various applications

Ease of use

- Toolmaster™: Patented system for automatic recognition of measuring system and accessories

- QuickConnect coupling: Easy, one-hand measuring system connection

- T-Ready™: Reduces waiting times by detecting and signalling sample temperature equilibration

- USB connection to computer/software

- Wide range of measuring systems for all kinds of applications

- Ethernet connection for remote control of the instrument through the company network

- Rheometer software: User-friendly application software with 21 CFR Part 11 compatibility

Wide range of accessories

- Temperature accessories in the temperature range from -150 °C to +1000 °C

- Application-specific accessories for DMA™ and DMTA measurements, rheo-optics, magneto- and electrorheology, interfacial rheology, UV curing and many other applications