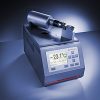

Fraass Breaking Point Tester:

BPA 5

The automatic breaking point tester determines the brittle behavior of bitumen at low temperatures.

The Fraass breaking point is the temperature at which the first crack appears in the coating of a thin, flat steel plaque, flexed under descending temperatures.

Key features

Benefits at a Glance

- Peltier cooling for the refrigeration of the test chamber

- Touchkey panel with large LC-display

- Software BPACon (optional)

- Calibration set (optional)

- Melting apparatus BPM 5 for steel plaque coating (optional)

Convenient Operation

- Test chamber refrigeration by Peltier elements. These solid-state cooling elements require a light auxiliary refrigerator only and you therefore avoid investing in a bulky and highly energy-consuming cooler.

Customized User Flexibility

- In connection with the BPACon software the breaking point tester serves as a research tool for different coatings. Not only test proceedings (e.g. variation of the bending force) can be easily watched via a graphic diagram on the PC screen, it is also possible to run Permanent Bending Tests in which the trend of the bending force vs. the temperature drops.

The Force Recovery Trend serves as the criteria for the elasticity of the material under test. The progression in plasticity and in cracking will be displayed numerically or graphically in different scales. With specially created curves of trends for bending or recovery force even very small, nearly not visible breaks of the material can be found with high precision.