VSTAR

The VSTAR system goes beyond basic water sorption to provide vapor and gas sorption analyses over a broad range of analysis conditions. Based on the fast and high-resolution vacuum-volumetric gas sorption technique.

VSTAR can deliver analysis results in roughly half the time required by classical DVS methods. Wide chemical compatibility allows you to measure adsorption/desorption isotherms and kinetics of many species (organics, alcohols, amines, and more).

Key features

Analysis results typically in just half the time needed by gravimetric methods

When analysis time is important, the VSTAR with its static volumetric system is the best choice. Uninhibited vapor sorption occurs when the sample is exposed to the pure vapor without any carrier gas.

This leads to faster equilibration compared to the time-consuming traditional gravimetric method, and higher-resolution isotherms in a fraction of the time. You can configure programmable vapor dosing profiles to fit your sample and analysis conditions based on the amount adsorbed/desorbed.

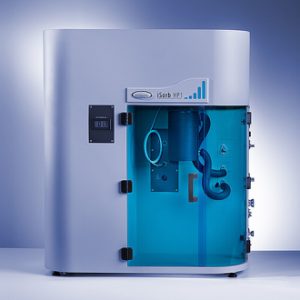

Complete temperature control system for homogeneous vapor concentration

The single thermostatically-controlled chamber of VSTAR contains both the pressure manifold and liquid vapor reservoir. It ensures true homogenous temperature for accurate and consistent vapor concentration. The programmable temperature, based on the adsorptive saturation pressure found in the extensive software library, is set slightly higher than this value to ensure a true adsorptive vapor phase.

The same or different sample temperatures are maintained in low-volume vessels that eliminate thermal gradients within the sample cell(s). This unique design offers independent temperature control for each station with multiple recirculators. Additionally, the interlocking chamber door keeps you safe from any hot surfaces.

Extensive vapor-gas library and high compatibility offer greater choice in adsorptives

VSTAR lets you use a comprehensive range of compatible vapors. Its vapor-gas library contains over 80 parameter files suitable for organics (saturated, unsaturated, and aromatic), alcohols, amines, water, and more.

Each vapor-gas file contains the essential data and equation of state coefficients for the extensive calculations performed during the analysis and for data reduction; the flexible architecture allows for additional gas files. The rugged 316 stainless steel construction coupled with the most suitable elastomers give the best chemical compatibility.

Low vapor pressure liquids: Analysis with 1, 10, or 100 torr sensors for increased sensitivity

To increase the sensitivity of some liquid vapor analyses, matching the vapor pressure with the pressure transducer range produces data with higher accuracy. Liquids that boil at high temperatures usually have lower vapor pressures at the analysis temperature, and the pressure transducer(s) used need(s) to be optimized. You can plan this in advance and configure each analysis station’s pressure sensor as required. The high-vacuum (turbo) model enhances very low pressure measurements.

In-situ sample preparation: Onboard degassing-to-analysis to reduce sample contamination

VSTAR makes sample preparation simple with in-situ degassing; sample degassing in the station followed by the analysis never exposes the sample to ambient conditions. This reduces overall analysis time and any accidental sample contamination. The outgassing furnaces are completely programmable with ramp and hold steps to create the necessary heating profile. Similar to the analysis protocols, the heating profiles are easily saved and quickly recalled.

Beyond standard experiments: VSTAR redefines what is measurable

Research requires discovering more than just a number. With the additional capabilities of VSTAR, you can measure a material’s water activity, hydrophobicity, hydrophilicity, heats (enthalpy) of adsorption/desorption, kinetics, and more. Extend your knowledge of your materials with the instrument’s ability to perform static temperature programmed desorption (TPD) and learn what it takes to regenerate your material. When gas adsorption occurs within the instrument’s sample temperature range it is also possible to perform CO2 and CH4 experiments to determine the material’s affinity for separating these gases.