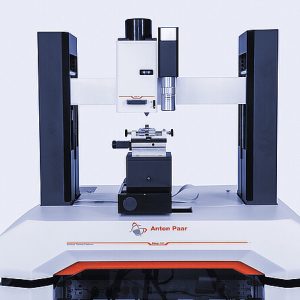

High Temperature Tribometer: THT

The analysis of friction and wear properties of materials at elevated temperatures has become increasingly important, especially for the development and quality control of combustion engine and power plant constituent parts. To meet the resulting need for quantitative data at elevated thermal conditions Anton Paar has extended its range of pin-on-disk tribometers with a powerful high-temperature version which can accurately simulate in-service conditions.

Key features

Technical features

- Two friction sensors minimize the effect of the thermal drift error on the friction measurement in a range from room temperature to 1000 °C.

- Surrounding heating elements combined with water cooling provide precise and homogeneous sample temperature control up to 1000 °C.

- Carefully designed sample- and ball holder for easy setup of tribology testing at extremely high temperatures

- Independent application of normal load and friction force measurement to avoid crosstalk between different force signals

- Single-direction rotating or angular reciprocating movement modes

- Continuous wear depth measurement

- Three testing parameters: standard, incremental, and user-defined mode

- “Modelization” software for simulating Hertzian elastic contact stress and strain distribution

- User-defined friction threshold auto-protection

- Fully conforms to ASTM G99, ASTM G133, and DIN 50324 standards

Additional capabilities:

- Testing under primary or high-vacuum conditions

- In-situ observation of wear under vacuum conditions

- Testing under inert gas atmosphere

- Tribology testing in liquids

Typical applications

- Cutting tools

- Automobile brake pad materials