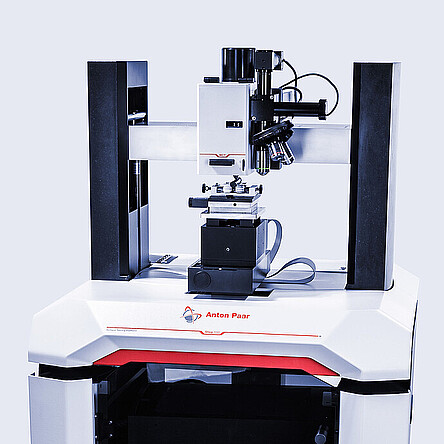

Revetest® Scratch Tester: RST³

The Revetest® scratch tester is the industrial standard widely used for characterizing hard-coated materials with a typical coating thickness exceeding 1 μm. RST³ is a reliable instrument for the characterization of both coating/substrate adhesion and surface anti-scratch resistance. Equipped with an easy-to-use software package, it is possible to perform scratch tests in a wide variety of testing modes, including simple scratch testing, advanced scratch testing (with pre-scan and post-scan), scratch map, scratch map by stage, user-defined scratch, etc. Anton Paar is the world leader in scratch testing with more than 1,500 Revetest® instruments sold.

Key features

Patented synchronized panorama mode

This unique feature is exclusive to Anton Paar scratch testers. It automatically synchronizes the recording of all sensor signals with the whole scratch image in perfect focus. In this way the measurement curve can be analyzed exactly parallel to the scratch picture on one page. Anton Paar holds the patents US 12/324, 237, and EP 2065695 for the synchronized panorama mode.

Measurements on curved and uneven surfaces

Due to its unique force sensor control, the Revetest® scratch system detects every surface deviation and the active force feedback corrects this deviation. By following the shape of the sample with total control of the desired load, RST³ is also capable of performing perfectly reliable measurements on uneven and curved surfaces.

Compliant with ASTM C1624, ISO 20502 and ISO EN 1071

Anton Paar works closely with standardization organizations such as ISO, ASTM, DIN, and others in order to support our customers to meet the high requirements they have for their own products, especially in quality control, where standards are often essential. By certifying our products accordingly, we can guarantee high-quality products and services in terms of safety, reliability, and environmental friendliness.

High flexibility on scratch measurements

The indenter tips in the indenter holder can be changed in an easy and quick way. Tips of different diameters and angles are available. The same indenter holder can be used for different kinds of tips such as spherical tips (1, 5, 20, 200, 800, … μm tips with open angles of 120° or 90°), Berkovich tips, or Vickers tips.

Automatic detection of critical loads

The critical load data is used to quantify the adhesive properties of different film-substrate combinations by using different sensors (acoustic emission, penetration depth, friction force) and video microscope observations. With the new easy-to-use software, all critical loads can be detected automatically. The user only needs to set up some threshold values and start the automatic analysis of critical loads (Lc). RST³ is the only scratch tester on the market with automatic detection of critical loads.