Brabender : Modular Cooling Die

Flexible product development on texturised plant proteins: Create different vegetable products with meat-like textures

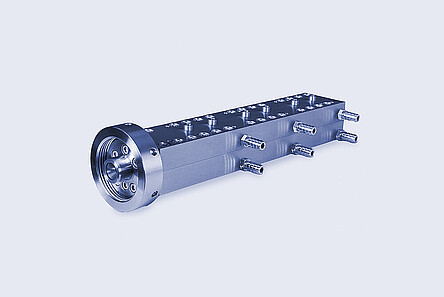

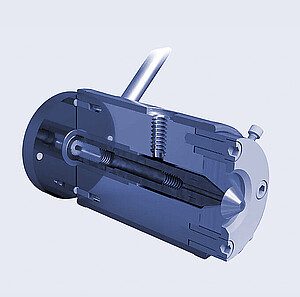

The Modular Cooling Die in combination with an R&D extruder is an ideal tool for the production of texturised plant proteins on a laboratory scale. The modular concept allows the extrusion of different product dimensions as well as different raw materials (e.g. wheat gluten or soybeans). A profound product development in the laboratory and pilot plants offer time savings and a higher flexibility compared to large production plants.

During the ongoing measurement, you keep the full control over the entire process. Six openings along the nozzle allow for example pressure or temperature measurement of the processed material. Structural changes can thus be recorded in real time and correlated with the resulting product properties.

The modular die construction consisting of a bottom and a top half ensures that different product sizes can be extruded. We are happy to adapt the die to your requirements!

Be a step ahead of the competition with the Modular Cooling Die in combination with a Brabender laboratory extruder in the product development of your meat-like plant proteins.