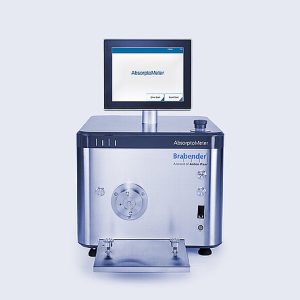

Modular Torque Rheometer: MetaStation 4

The market-leading Brabender MetaStation is a versatile, modular drive unit and torque rheometer for determining the processability and material characteristics of different plastics and plastifiable substances, compliant with key ASTM standard methods. Tailor it to your specific PVC, rubber, or thermoset testing needs, using our portfolio for varied blade geometries, mixer sizes, and temperature control. In addition to batch-wise compounding and mixing, continuous processes are also possible via the use of single- and double-screw extrusion attachments of different scales. MetaStation: Today’s configuration flexibility, tomorrow’s infinite possibilities.

Key features

Your path to worldwide product qualification

The MetaStation adheres to a wide range of national and international standards on the mixing of plastic and rubber compounds, including key ASTM standard methods. This ensures you can qualify your products for international trade and that they meet the stringent requirements of global markets.

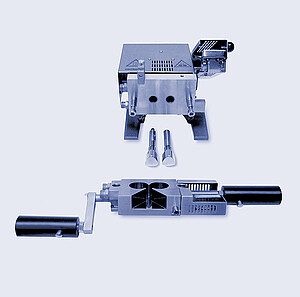

From PVC to thermosets: MetaStation’s versatile mixer attachments

Switch between mixer modules in under 15 minutes and quickly cover a broad array of applications. The modular concept of MetaStation lets you tailor the instrument to your needs. It offers a portfolio for blade geometries, mixer sizes, and temperature control solutions for applications such as testing PVC (using the W 50 EHT type mixer), rubber (with the 350SX type mixer), and thermosets (via the MB 30 type mixer). In addition, filling solutions designed specifically for the mixer attachments reduces errors and maximizes convenience. The optimized mixer design makes opening, disassembly, and material removal easy – cleaning is twice as fast compared to previous generations.

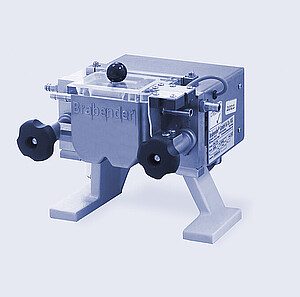

Extrusion insights: Your shortcut to improved product quality

Along with batch-wise compounding and mixing capabilities, our extrusion attachments of various scales open the door to continuous processing. Explore the potential for testing your materials through extrusion at both lab and pilot scales without disrupting your production resources. This lets you delve deeper into understanding the correlations between critical process parameters and final product quality, and make adjustments that optimize your manufacturing processes.

MetaBridge: Your gateway to data excellence

The MetaBridge operating software enables access to your measurement data from any device or location. Export and share data seamlessly with colleagues or third-party systems like LIMS, ERP, or via email. Adhere to your preferred ASTM standard with just a click and transition effortlessly between mixing and extrusion applications. Harness the power of the software’s reference curve feature to monitor material quality in real time, receiving automatic feedback on compliance with specifications. Plus, the software’s correlations add-on lets you compare a large number of measurements, providing an optimal understanding of your materials.

Specialized solutions for demanding applications

A diverse selection of steel alloys and advanced coating materials for our mixers guarantees measuring precision and durability throughout the entire lifespan of the instrument, even when handling highly corrosive and abrasive substances. The MetaStation, featuring the MB 30 mixer, is the premier solution for accurately determining the crosslinking properties of thermosets according to DIN 53764 standards.