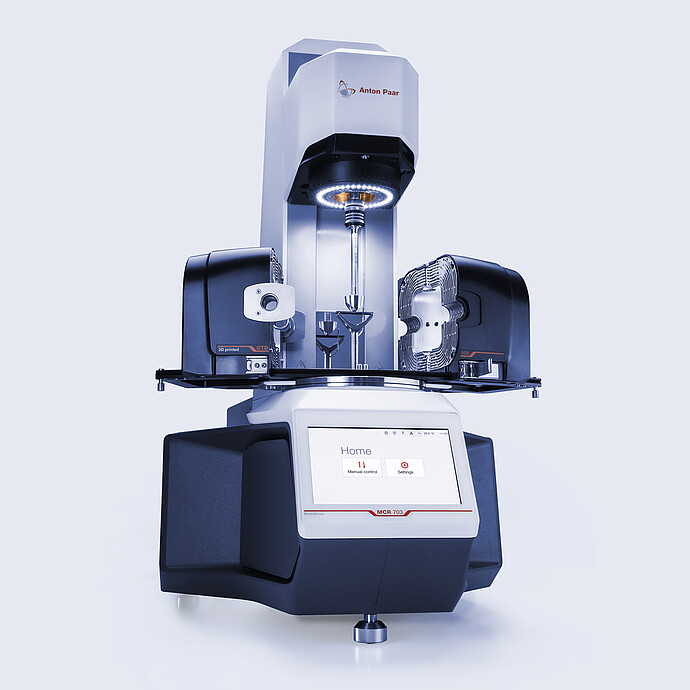

Dynamic Mechanical Analyzer:

MCR 703 MultiDrive

The MCR 703 MultiDrive is like no other DMA on the market. Along with dynamic mechanical analysis in tension, torsion, bending, and compression, its unique axial-torsional DMA mode opens up new fields of material characterization – such as determining the Poisson’s ratio of isotropic materials and characterizing anisotropic material behavior. Air-bearing-based drive units and an optical encoder ensure the highest sensitivity in force, torque, and displacement measurements for soft and stiff materials. Automatic recognition and alignment of measuring systems and accessories, one-handed coupling, and touchscreen control enable quick setup and easy sample preparation. With 200+ accessories for comprehensive material characterization, you can transform your DMA into a fully-fledged rheometer, tribometer, UTM Micro, or powder rheometer.

Key features

Dynamic mechanical analysis like never before

MCR 703 MultiDrive redefines the dynamic mechanical analysis (DMA) of liquid, soft, and solid samples – enabling you to perform DMA in tension, torsion, bending, and compression, as well as thermomechanical analysis (TMA) with one instrument.

You can also carry out axial-torsional DMA to determine the complex Young’s (E*) and shear (G*) modulus as a function of temperature, frequency, time, or humidity within a single experiment. This unique feature allows enhanced characterization of anisotropic materials and can even determine the Poisson’s ratio of isotropic materials within a single test.

Achieve unprecedented measuring quality

The air-bearing-supported upper rotational and lower linear drives, as well as the optical encoder technology, empower you to perform linear dynamic mechanical analysis across a force range of 0.5 mN to 40 N, and torsional dynamic mechanical analysis in a torque range of 0.2 nNm to 230 mNm.

State-of-the-art convection temperature devices ensure homogeneous temperature distribution from -170 °C to +1,000 °C and provide the accuracy necessary for controlling both the sample temperature and relative humidity. Each standard measuring system includes an integrated temperature sensor located close to the clamped sample, offering a precise and reproducible measurement directly at the sample.

The smartest DMA, from start to finish

Avoid back-and-forth between your PC and the dynamic mechanical analyzer, and use the touchscreen exactly where you need it to prepare your test. QuickConnect enables one-handed measuring system changes in seconds, while Toolmaster auto-recognizes and configures all accessories. Fully automated procedures guarantee precise and repeatable alignment of the measuring systems – eliminating time-consuming setup processes and the need for manual intervention.

The powerful RheoCompass software includes wizards and a wide selection of predefined templates, allowing you to streamline your workflow and effortlessly generate the ideal test procedure for your specific application.

More than just a dynamic mechanical analyzer

The MCR 703 MultiDrive’s cutting-edge hardware and electronics put you at the front of the pack for years to come – with the added competitive flexibility to do whatever you want. Transform your MCR 703 MultiDrive into a fully-fledged rheometer, tribometer, mechanical tester, or powder rheometer with over 200+ application-specific accessories. In addition to classic dynamic mechanical analysis, it enables comprehensive characterization of liquids, solids, powders, and even mechanical parts.

Specialized solutions, endless applications: explore new testing possibilities

The MCR 703 Space MultiDrive maximizes working space to accommodate accessories and complementary measuring instruments. Anton Paar’s in-house development and production team provides devices and accessories tailored to a range of specific applications, including solutions for characterizing solids immersed in a liquid. Shafts can also be combined with any disposable or customized geometry, and for testing powdery samples. Anton Paar offers material pockets in combination with the typical DMA measuring systems in bending mode.