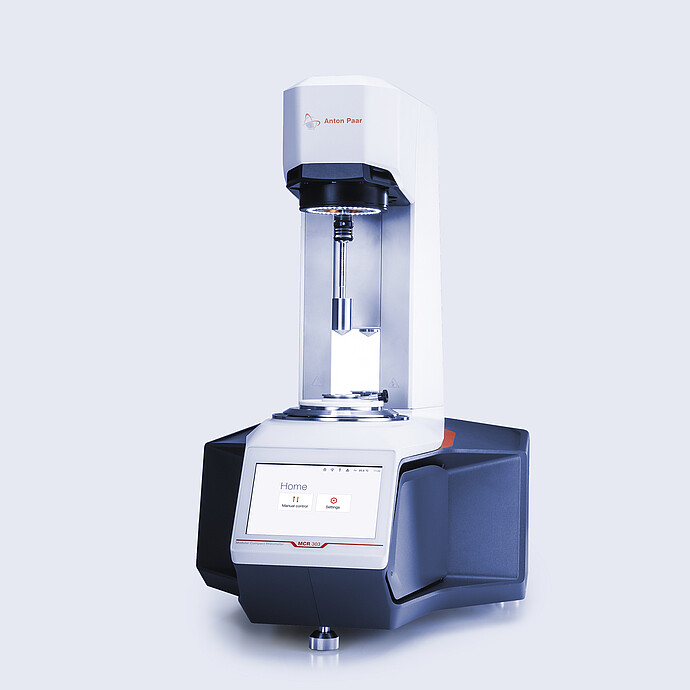

MCR 303/503/503 Power

Welcome to the MCR series: A new era in rheometry

The exciting new rheometers – MCR 303, MCR 503, and MCR 503 Power – are based on new modular platform architecture, enabling outstanding measurement quality and ease of use to ensure excellent reproducibility and remarkable productivity. With a wide range of configurations available, including the option to transform the modular compact rheometer into a material characterization platform, the MCR series is ready to meet all your current and future requirements.

Key features

The most precise rheometer

The most precise rheometer to date, the new MCR enables previously unthinkable applications and enhances every measurement.

- Unmatched minimum torque of 0.2 nNm in oscillation

- Exclusive high-frequency data: Up to 200 Hz

- Breakthrough normal force accuracy 1 mN

- Stable motor: Drift-free high-precision measurements over weeks

- Fastest electronics: Monitor even the quickest curing reactions

- Best-in-class thermal stability: Eliminates temperature gradients in large solids

The fastest rheometer

With an unprecedented focus on productivity, the new MCR rheometer helps you increase output for a quicker return on investment.

- Next-generation electronics: Delivers results up to 60 % faster

- Quick boot time: Starts in 6 seconds; 7× faster than other systems

- QuickConnect: Mount measuring systems in seconds with one hand

- TruRay and trimming mirror for precise sample preparation

- With fastest global support: 35+ subsidiaries and experts help at no cost

- More than instruments: Complete solutions from one trusted source

The smartest rheometer

Let the new, intelligent MCR take work off your hands, so you can focus on things that really matter.

- Touchscreen: Full sample preparation directly at the instrument

- Electronic leveling: Prevent errors from improper setup

- Automatic temperature calibration: From -160 °C to +600 °C

- Sustainability: 56 % less energy use with air Peltier systems

- Sample-adaptive controller: No manual presetting needed

- Toolmaster: Automatic detection of tools and accessories

- Auto gap control: Compensates for thermal expansion

The most adaptable rheometer

With the broadest accessory range available, you’ll be able to realize whatever great ideas you have in the decades ahead.

- 7,000+ geometries: Cover every material, surface, and shape

- 40+ temperature devices: From -170 °C to +1,000 °C

- Multiparameter options: Add pressure, humidity, voltage, and more

- RheoOptics and structure analysis: Rheo-Raman, impedance, and more

- Extended applications: Analyze interfaces, powders, bitumen, and more

- Customized solutions: If it’s not in our portfolio, we’ll build it for you

- More than a rheometer: A characterization platform

- Learn with us: Webinars, books, and the Rheo Academy

The ultimate rheometer software

RheoCompass is accessible for everyone, with a new user interface and touchscreen for quick instrument operation. From routine QC testing to scientific applications, it’s ready for any challenge.

- Touchscreen interface with intuitive navigation and multilingual support

- 250+ predefined templates with guided touch control

- Customizable templates, extensive analysis tools, and pharma compliance

- Specialized analysis for tribology, powder rheology, and LAOS data

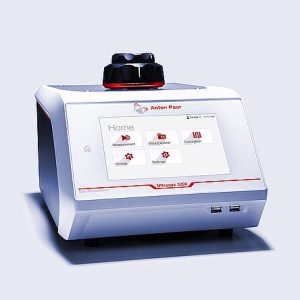

More than just a rheometer

Our modular compact rheometers go beyond rheology – they are powerful characterization platforms for a wide range of applications, including tribology, powder analysis, dynamic mechanical analysis, and mechanical testing.

- Powder testing: High-sensitivity powder behavior analysis

- MCR Tribometer: Expanded tribological testing, including measurements of breakaway force and Stribeck curves

- Dynamic mechanical analysis (DMA): Deep insights into material properties such as modulus, damping, creep, glass transition temperatures, and more

- Mechanical testing: Texture and material testing with high precision – from peel and puncture tests to compression and flexure analysis