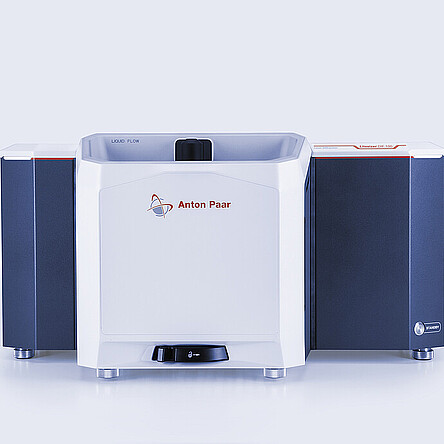

Laser Diffraction Particle Size Analyzer:

Litesizer DIF 100

The Litesizer DIF series offers advanced particle sizing from 10 nm to 3.5 mm, drawing on nearly 60 years of laser diffraction expertise. This laser diffraction particle size analyzer has a best-in-class optical setup featuring powerful 10 mW and 25 mW lasers and the widest range on the market of detected diffraction angles from 0.01° to 170°. The Kalliope software simplifies particle sizing, requiring no extensive training – measurements start with just three clicks. The Quick-Click system allows easy switching between dispersion units, minimizing errors. Safety features for both liquid and dry dispersion ensure effortless, secure operation.

The robust metal housing and the isolated optical bench deliver reliability everywhere: from harsh environments, to high-tech laboratories.

Fueled by our pioneering legacy, this is next-generation laser diffraction technology – the Litesizer DIF series: From First to Best.

Key features

Particle sizing in any environment

Anton Paar’s Litesizer DIF is suitable for heavy industries. It is made of high-quality components inside and out. Sturdy metal housing encases durable optical elements. Litesizer DIF is built to endure harsh environments: No dust or powder can penetrate into the optical bench of the instrument, and the inside of the instrument is isolated from possible direct vibrations at the production site. All of this means savings on upkeep and repair costs.

Kalliope: The benchmark software for particle sizing

With Kalliope, users immediately know how to get started, via the one-page-only workflow (setting parameters, acquiring and working with results). Additionally, the QC mode offers consistent reliable measurement results by customizing user management and locking delicate settings. The instrument in QC mode gives simple feedback if your product is within your defined limits. This means results in just three clicks and less training for new users. In addition, a pharma option with data security functions, user management, and audit trails is included, making Kalliope compliant with the US FDA’s 21 CFR Part 11.

Efficient dispersion, maximum safety

Litesizer DIF’s Quick-Click feature connects the dispersion units in just one move – no hassle with cables, tubes or pipes. The obscuration level indicator allows monitoring of the sample amount while adding it, ensuring the right amount from the start.

The Dry Jet dispersion unit has a suction check and built-in dust cover to minimize the risk of powder spread.

The Liquid Flow unit automatically checks for sufficient liquid before sonication, preventing overheating. A dedicated module with high chemical resistance is available for aggressive liquids.

The Liquid Flow Imaging unit combines laser diffraction and dynamic image analysis adding shape parameters of particles from 5 µm in size.

On quality, we lead the way

Litesizer DIF is the perfect tool for particle analysis due to its high-quality manufacturing. It features high-grade hardware, empowering the instrument to collect superior raw data. This laser diffraction particle size analyzer enables users to measure a broad range of samples, covering particle sizes from 0.01 µm to 3,500 µm, all with a single analyzer – without the need for additional investment.

Less investment, saved bench space – compatibility across the board

Compatibility of dispersion units between Anton Paar’s Litesizer DIA and Litesizer DIF instruments reduces investment costs and lab space usage. On top of that, all Litesizer instruments can be operated using a single PC with the Kalliope software installed.