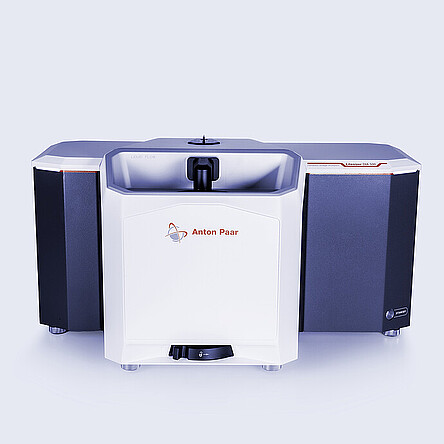

Dynamic Image Analyzer:

Litesizer DIA 100

With Litesizer DIA Series, our dynamic image analyzer, you can easily and reliably characterize the size and shape of particles via analysis of their direct images. In just one step, quickly switch among three modules that use dispersion liquid, compressed air or free-fall for excellent dispersion of your sample. Rely on the automation of feeding rate adjustment and rinsing of liquids, and conduct measurements with only minimal training.

That’s particle analysis at the touch of a button – only with our dynamic image analyzer.

Key features

Get particle size and shape in one measurement

Measure particle sizes ranging from 0.5 µm to 16,000 µm with precision, and detect single outlier particles in large samples. Utilize a market-leading liquid dispersion range of up to 2,500 µm. Replace traditional sieve analysis with fast, safe, and dynamic image analysis to gain a deeper understanding of how particle size measurement can optimize your processes.

Optimize measurements with Kalliope software

Start your measurements in just three clicks. Analyze particle size, shape, and images all in one digital space with our dynamic image analyzer. Easily filter particles by specific size and shape using Kalliope’s powerful features. Control all your Anton Paar particle-sizing instruments from the Kalliope particle analysis software platform.

Prioritize operator safety

The Litesizer DIA dynamic image analyzer incorporates multiple safety features to protect the operator. Stay safe with a cover that prevents dangerous sample spread. Prevent overheating with liquid level recognition before sonication. Ensure containment of hazardous samples with automatic suction checks. Comply with relevant safety standards, including EN 61010:2010 and ISO 12100:2011.

Three dispersion units in one dynamic image analyzer

Measure samples using Liquid Flow (liquid dispersion), Dry Jet (compressed air), and Free Fall (gravitational fall) dispersion units. Experience unmatched flexibility in a dynamic image analyzer with the ability to quickly and easily switch between units with the Quick-Click feature, eliminating the hassle of cables and tubes.

Save time with automation

Automatically optimize sample feeding rates, and automate filling, draining, and rinsing tasks to focus on more important work. Enhance data quality and speed up analysis with auto-filtering of particles.