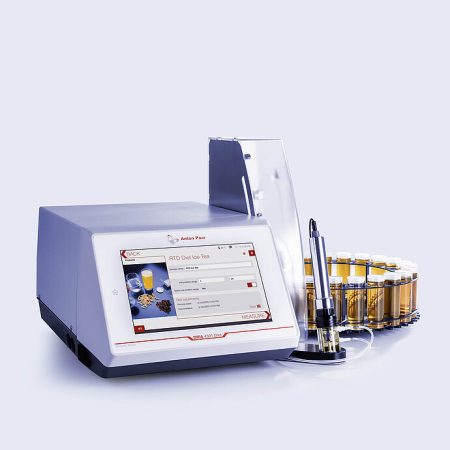

Sugar inversion analyzing system: Soft Drink Analyzer M

For products that use sucrose as a sweetener, Soft Drink Analyzer M determines the sugar inversion process digitally in just 3 to 5 minutes and without the need for forced inversion. It uses a unique combination of density and sound velocity technology in one system and is the ideal instrument for measuring sugar content in soft drinks, syrups, and HFCS.

Combine Soft Drink Analyzer M with a sample changer (and optionally with a %Diet measuring module) for measuring syrups and degassed samples, or use it in a multiparameter system for QC out of the final package.

Key features

Measure sugar solutions in any state with one instrument

Soft Drink Analyzer M determines the concentration of fresh, actual, and inverted sugar as well as the degree of inversion in syrups and finished regular soft drinks. This means you can omit forced inversions – one step less in your workflow. Soft Drink Analyzer M derives the concentration from density and sound velocity results.

Both results are measured from one sample in one go. The automated detection and compensation of a sample’s viscosity lead to highly accurate results (also for viscous syrup samples). The sound velocity cell withstands pressures up to 8 bar, so that you can analyze all samples, from syrups up to carbonated drinks, with one instrument.

The most accurate density and sound velocity results you can get

New technology, such as the patented Pulsed Excitation Method and intelligent features, deliver the best results on the market, so you can detect even the smallest deviations in your continuous production and react quickly to minimize downtimes.

- Accuracy up to the 6th digit

- Repeatability: 0.000001 g/cm³ (density), 0.1 m/s (sound velocity)

If the filling is incorrect, FillingCheck™ generates and records filling warnings for both the density and the sound velocity cells. In addition, ThermoBalance™ temperature management eliminates drifts caused by temperature stress (requires only one adjustment at one temperature).

Traceable documentation of results

The sensitive yet robust 10.4” PCAP touchscreen, an optional keyboard, and a barcode reader simplify your data management. Additionally, you can print out your measurement reports in a standardized layout or transfer measurement data to your individual data system to make each sample traceable as required by your standards.

Measure sugar inversion, %Diet and CO2 with one system (PBA-SID)

The Packaged Beverage Analyzer M for soft drinks performs quality control out of the final package without sample preparation. No matter which type of soft drink has to be analyzed, the system with its master instrument Soft Drink Analyzer M, determines the °Brix value, the sugar inversion process, and the dissolved CO2 content using only 150 mL of sample.

To modify your system for diet beverage analysis, the DietQC ME with the option for uncolored drinks is the solution. Choose modules for dissolved oxygen, pH, or turbidity to complete your system for final beverage analysis. Within three to five minutes, you’ll know about the quality of your final product.

Automated analysis of diet syrups and degassed beverages

For automated analysis of diluted diet syrups and degassed final beverages, combine Soft Drink Analyzer M with automatic sample changers, such as Xsample 320(automated filling of a single sample), Xsample 330 (additionally performing an automatic cleaning), or Xsample 520 (which automates filling and/or cleaning of up to 24 samples in a row).

Combine the master instrument with Anton Paar’s DietQC diet module (to also measure uncolored diet drinks) or a module for pH determination. An optional barcode reader added to Soft Drink Analyzer M automatically identifies each sample name, making every measurement traceable for your documentation.